The rise in the price of feed raw materials, increase in production costs (feed, energy, fertilizers, veterinary drugs, etc.) are the conditions that affect all pig producers on the market.

But still, there are methods that can reduce the cost of feed.Of course, this is not a question of "miraculous tools", but only about the long-known and not subject to time optimization of the feed regime. All these methods in addition to reducing feed cost positively affect the environment, humans, and animals, and even improve the performance and quality of the slaughtering carcass.

10-step program to reduce feed costs.

1. "Do not feed"

This statement does not contradict the aforesaid.

For fattening pigs: If the cost of feed is too high, and the cost of piglets is low, then it is worthwhile to think about reducing the fattening weight "at the permissible level" with a simultaneous increase in the fattening place. These reflections are relevant when:

- The cost of feed exceeds 20 euros per center;

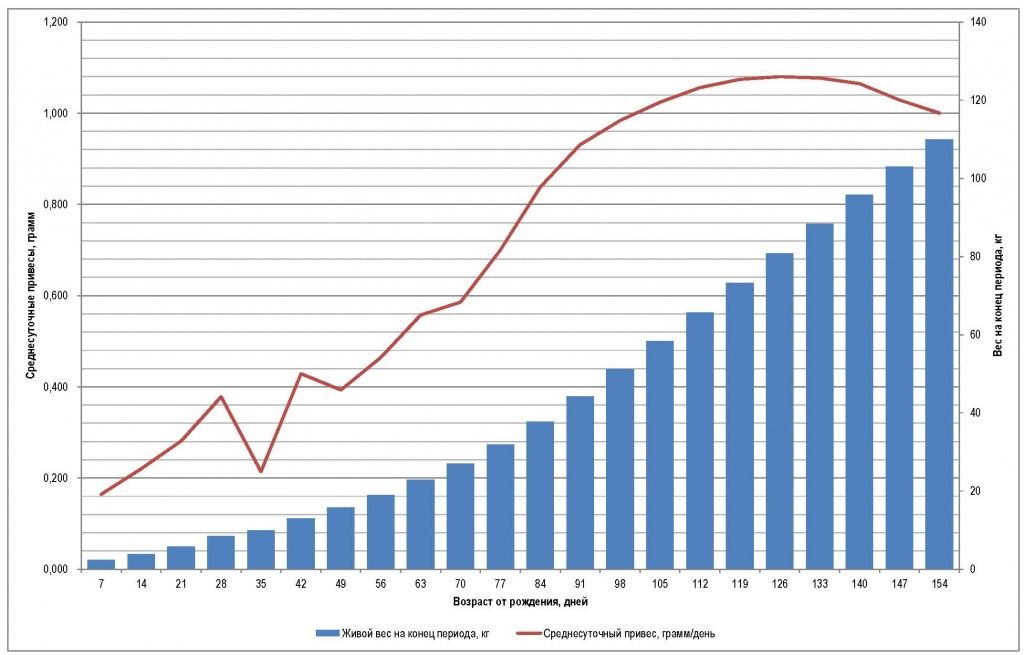

- Average daily weight gain in the final period of fattening falls below 600 g;

- The feed consumption of the "last kilogram" exceeds 4 kg of feed per 1 kg of gain;

- The level of productivity of the enterprise/turnover is low;

- The price of meat falls.

So 1 kg of the weight gain in the final period of fattening at 105/115/125 kg is ... .kg of feed (Table 1)

Table 1. Cost of fattening in the final period

| Gains (g / day) | Live weight (kg) | ||

|---|---|---|---|

| 105 | 115 | 125 | |

| 700 | 3,9 (2,9) | 4,5 (3,1) | 5,3 (3,3) |

| 750 |

3,7 (2,8) |

4,2 (3,0) |

4,9 (3,1) |

| 800 |

3,5 (2,7) |

3,9 (2,9) |

4,6 (3,0) |

The figures in parentheses are for the entire fattening period from 30 to 105, 115 or 125 kg of MF

With revenues below 1.50 euro/kg of bottom hole weight (net) and feed costs higher than 20 euro/cf fattening to 125 kg of live weight, even with a weight gain of 800 g are already critical. With feed costs from 25 to 30 euro / t, the marginal revenue, depending on the productivity, is reduced from 5 to 15 euro/goal.

For sows: In practice, it is often said that pregnant sows usually receive too high energy supply to increase the weight of piglets at birth and that sows are the necessary condition. But numerous experiments have shown that providing animals with energy by + 10% more, compared to the energy at a normal level, does not give any advantages.

Conversely, sows receiving excess energy resulted in fewer pigs, whose weight was not higher, consumed less food and lost more weight during the suckling season.

2. "Expand" the productivity

The following methods for fattening are under review:

- Formation of homogeneous groups (optimal - separation of animals by sex);

- Individual feed curves for each enterprise; (For example, if at the beginning of fattening there were "problems at the start", such as diseases, stress or obesity of animals earlier / stronger, then do not overdo them at the end of fattening);

- Consumption of net food from 30 to 115 kg of live weight at the level of weight gain of 700 g is 265 kg, with a gain level of 800 g is 245 kg - so the goal is uniformly growing pigs and more revolutions;

- Optimize the frequency and amount of feed distribution (here, of course, sensors on feeders with "smart" feeding control help are of use);

Do not allow a sharp change in diet during fattening (without a sufficient period of transition). For example, with a sharp change in the components of mixed fodder from wheat/barley to maize/triticale, 70 kg pigs in the middle of the fattening period showed a decrease in weight gain, generally received a lower level of weight gain and 1.5% less lean meat than pigs with a smooth transition.

Growing piglets to get more pigs per sow per year is also interesting because the need for a sow's life is equally distributed to all piglets.

3. "Organize" feeding

Active management of feeding means a year ahead planning along with the management of crop rotation, the purchase and sale of feed materials and optimal loads on warehouses, the use of discounts on the amount of purchased lots (group purchases), the use of seasonal by-products planning, control of feed by quantity, quality and exchange value ... .

4. Cheap does not mean profitable

So expensive, but in terms of quality, a more saturated mineral fodder, compared to a cheap offer, reduces feed costs by saving on protein components or by reducing feed consumption during the fattening period, thereby reducing the burden on the environment (2-4 Euro/head).

Also, other "cheapeners" in the diet are beneficial only in case the productivity indicators still correspond the norm and they, at least, cover additional costs for work/storage/risks.Therefore, the usual comparison of prices between individual feed components is not sufficient.

New raw materials need to be evaluated in accordance with the ideal protein concept. At least, it is necessary to take into account nutritionally identical diets with and without a "new component" and such moments as taste, availability, impact on productivity. As a rule, it requires a recalculation of the cost price.

For sowsTwo mineral feeds are needed, a cheaper mineral feed for pregnant sows and a more saturated mineral feed for lactating sows.

5. No confidence in supplements with "special" action

Feeds and feed additives have their specific strengths - for nutrition, taste, technology, hygiene - it should be used in the diet. Additional effects that are often advertised can not often be realized, even if productivity and management are the proper ones. Confidence in fictitious "special" effects often costs too much money!

6. "Chic" often does not pay off

A satisfactory diet for fattening pigs within the boundaries of 12.8-13.2 MJ OE / kg and other nutrients corresponding to this energy level is a "safe" feeding. Plus 1 MJ / kg of feed above this level costs 2-4 euro / head with an increasing trend due to the high price.

When feeding piglets, they often talk about very (very) good "best / expensive" components or overestimate the level of nutrients. Simple fodder concepts, timely feeding, multiple feedings per day, timely change of feed for a suitable next feed are Always more profitable and safer than trusting "high price".

When comparing different feeds for pigs, a price fluctuation of +/- 100% was established with very similar results.

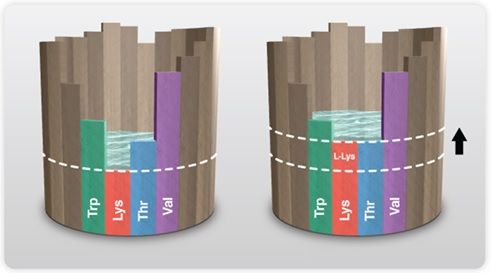

7. Timely feed change - phase feeding

Phase feeding (at least 2) is the standard. Now there is a tendency to increase the feeding phases and change food from expensive to really very cheap (saving 2-3 euro/goal).

Each stage of cultivation requires food with a certain nutritional value

The range of 30-110 kg of live weight:

- Lysine (per 1 kg of feed) from 10.5 g to 7 g;

- Phosphorus (per 1 kg of feed) from 5.5 g to 4.0 g;

- Vitamin A (per 1 kg of feed) from 7000 M.E. Up to 4000 M.E. etc.

For piglets, when the cost of feed is very high, one needs 3 types of feed: prestarter-feed for weaning, starter 1 to 20 kg of live weight and a starter 2 after.

For sows, the use of two mixed fodders results in savings of about 10 euro per a sow per year: compound feed 1 for young sows and/or the second period of gestation and compound feed 2 for the first period of gestation and/or old sows.

8. Simple solutions help

Often the phase feeding, individual feed curves, the compilation of homogeneous and timely groups are obstacles (see point 1). Phase feeding works simply: the proportion of the starter is reduced with the aging of the animals, and filled with grain, or mix the starter and the finisher, gradually replacing the first with the second. And these two mixed fodders are fed in different ratios for young, middle-aged and older animals.

It is easy and profitable to feed sows with mixed feed according to this scheme: ½ feed for lactating sows plus ½ grain is fed for 10 days before and 2 days after farrowing.

And what about the roughage for pregnant sows (minus 30 euros per sow per year)? Silo can be planted together with a neighboring enterprise that breeds cows. For it, of course, it is necessary to take some technical/organizational and organizational changes.

As an alternative to roughage, there may be silage corn, corn silage, grain silage, etc.). One can think of harvesting these feeds and on one's area as a replacement for expensive raw materials - a source of raw fiber.

9. To improve fodder technique

The most expensive feed technology with all the technical "bloat" is good to the extent that it is observed and controlled.

Often the dispensers checking shows that there can be whole "worlds” between "must be" and "is". In some feeding troughs, because of the stratification, mineral fodder does not fall (examination of the sample for raw ash), etc.

Double cleaning of cereals (at harvesting and before feeding) allows to reduce by 20% pollution with toxins, allows to increase feed intake and get plus about 20 g of gain per day.

The optimal mill’s settings save expenditures on electricity and provide the desirable grain crush (about 50% of fractions – <1 mm / about 40% – <2 mm / about 10% – <3 mm without halves or whole grain). The experience shows that “new” mill beaters led to a 26g a day weight gain.

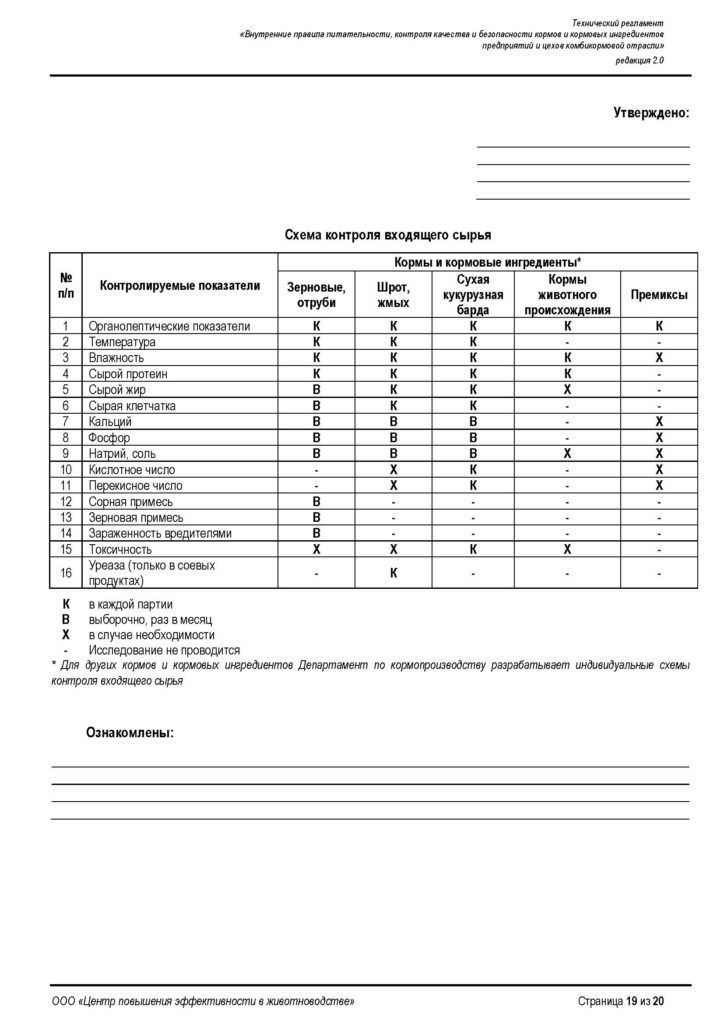

10. Identify, monitor and improve critical points

Of course, one can wait until the feeding auger feed screw has broken, and the results of the animals will display it until the mold completely covers the plastic container for storing the feed ...

But one can make up a list of items that one needs to monitor, determine the necessary intervals of the control (feeding plan, plan for sampling, hygiene plan, productivity evaluation plan) without additional costs and perform it in time before the "catastrophe" occurs and one needs to Eliminate it urgently ...

Hidden productivity losses in pig-breeding enterprises due to the "out of habit", "old-fashioned" work is estimated at 30-50 grams of average daily weight gain, and for piglets - 1 pig per sow per year!

conclusions

The presented "10-step program for reducing feed costs" contains expedient measures to reduce feed costs with varying degrees of efficiency and greater or lesser costs.

It will pay off: try out individual proposals, adapt them to the needs of a particular enterprise and gradually introduce them. Try it. "Checklists for pigs" can help in this".

This article was published on October 24, 2007, so the prices quoted in it in euros do not correspond to the current level. But in themselves, the methods of cheapening, as they say in the article, have long been known and are not subject to time.

Translator's notes