The introduction of a truly new technology is a rare phenomenon in modern animal husbandry. As for this area, progress is often due to the improvement of long-known processes, their withdrawal to a higher level of capabilities. The same applies to feeding. The physical form of the feed has a significant effect on the effectiveness of the use of pigs nutrients and the functional state of the digestive system..

There are two main methods of feeding in industrial pig breeding:

- dry;

- liquid.

As the intermediate distinguish still wet (semi-dry) and wet types, when dry feeds are automatically moistened or mixed with water shortly before they are sent to the feeders.

What is the best way to feed pigs? Probably, the final answer will be given to that difficult issue in the years to come.

Dry feeding of pigs

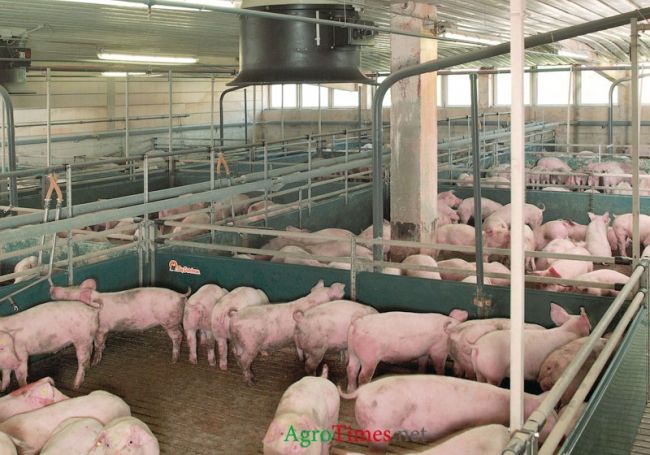

70-75% of pig farms in the world use dry feed for feeding pigs.

Among the advantages of "dry" feeding of pigs, they are following:

- Balanced granular fodder is more stable in terms of sanitary and hygienic characteristics;

- The process of heat-moist processing of feed (granulation, expansion, extrusion) increases the availability of dietary components for gastrointestinal enzymes. This contributes to a better assimilation of feed nutrients (by 10-20%) and an increase in the productivity of animals (by 5-25%). However, such treatments do not reduce the number of cases, for example, salmonella infections;

- Lower investment costs for installation and maintenance of necessary equipment.

- Dry feeding often causes significant changes in physiological processes in the gastrointestinal tract, contributes to the occurrence of gastritis and other diseases, requires medical intervention;

- The timing of the behavior shows that 18-25% of animals (especially young animals) are in constant motion between feeders and drinking bowls, interfering with the rest of others, and the loss of feed at the same time reaches 3-9%;

- Considerable damage is caused by increased dustiness of the premises, which negatively affects both animals and service personnel. Ashen particles of dry mixed fodder can make up to 20% of its quantity, the amount of animals suffering from pulmonary diseases increases by 8-10% through the dust.

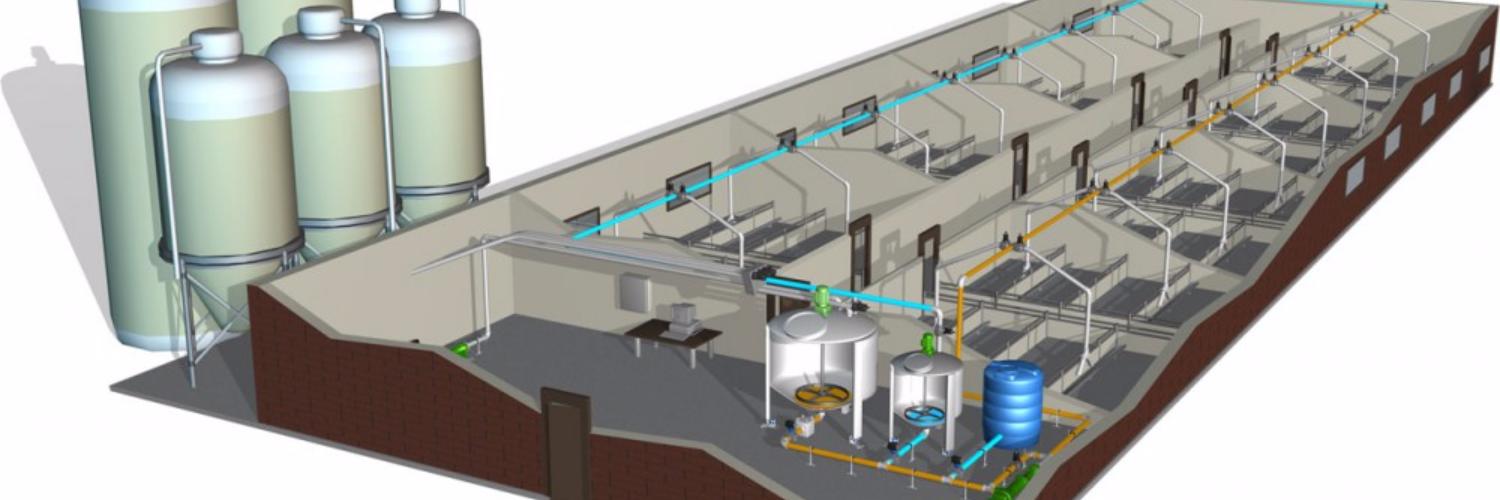

Liquid feeding of pigs (moisture of feed up to 75%)

Ireland is the leader in "liquid" feeding of pigs among European countries - 90% of all farms, as well as Germany, Denmark (including over 60% of large pig farms), Holland - up to 50% of the total number of livestock. In Finland over the past 5 years, more than 90% of the pig farms that have been put into operational use a liquid-type feeding system.

Advantages of "liquid" feeding of pigs:

- The possibility of using waste and secondary food products (milk, brewing, sugar, alcohol, flour, meat processing, butter, bakery) and microbiological industry. This is an important advantage, it makes it possible to reduce the costs of grain feeds and reduce the cost of production.

- Liquid food is more in line with the physiological needs of pigs and provides an opportunity to provide a gradual replacement of rations;

- More accurate dosing;

- Simplified introduction of additives (premixes, medications, etc.);

- Reduction of feed losses;

- Possibility to refuse drinkers;

- In comparison with dry forages, the consumption of liquid fodder increases to 5%, increments increase to 6%, the conversion rate (costs) of feed is reduced to 10%;

- Decreases the amount of excrement, which positively affects the economic and environmental aspects of production;

- At enterprises in which different age groups are in the same premises, different recipes can be simultaneously used with the help of a liquid feeding system;

- The possibility of delivering large volumes of feed over a short period of time over long distances with the help of pipelines;

- The process of liquid feeding is flexible, provides the opportunity to promptly adjust the diet without the participation of a feed mill, in particular, to mix ingredients, introduce them gradually for the adaptation of the animal;

- According to JSC "Omsky Bacon" (Russia)specialists, The introduction of liquid feeding (after the dry type of feeding) allowed to reduce the number of personnel by 25%, reduce energy costs, reduce the influence of the human factor on the feeding process;

- A very important advantage of "liquid" feeding - the possibility of fermentation of the feed mixture. Fermentation of feeds changes their biochemical composition increases the bioavailability of substances.

Fermented liquid feeding of pigs

FeedingFermented liquid food(PRK) positively affects the morphological characteristics of the mucous membrane of the gastrointestinal tract, stimulates the immune system of pigs. Feeding sows withFRC significantly reduces the vertical transmission of enteropathogenic microorganisms - dangerous pathogens for many diseases of digestive pigs.

There are the following types of fermentation:

- Autofectivity(Uncontrolled, natural) - some components of the diet (cereals, dairy products) contain lactic acid and other beneficial bacteria, which in the process of reproduction by the products of their metabolism (mainly organic acids) reduce the pH of the feed. Studies conducted on 320 Dutch farms showed that subclinical forms of salmonellosis in piglets that were grown on liquid food were diagnosed 10 times less often, and outbreaks of colibacteriosis were registered 25% less than among pigs on dry food. But uncontrolled fermentation is unstable and can lead to uncontrolled consequences;

- ChemicalFermentation of feeds occurs by the addition of organic acids (more often milk) and bringing the pH of the feed to 4.0. At the same time, the cost of acid pays off by increasing the productivity of animals;

- ControlledMicrobial fermentation of feeds is carried out due to the introduction of proteolytic, cellulozolytic and other bacteria that have a probiotic effect, and have a positive effect on the stability of the anendomicrobiocenosis of animals.

The technology of liquid feeding of pigs is a promising and resource element of an integrated system of the efficient use of resources in animal husbandry.

Disadvantages of "liquid" feeding of pigs:

- High cost and equipment costs (investments to implement the system pay off in 3-5 years);

- Liquid feeds have a short shelf life;

- There are threats in case of violations of the cleaning regimes of piping systems, feeders, this system needs daily monitoring;

- With such a feeding system, high humidity is noticed in livestock premises, which negatively affects animals (especially in winter);

- Non-observance of rational proportions of fodder mixtures, increase in humidity more than 80% increase in humidity lead to a number of negative consequences: the rate of passage of feed masses by the gastrointestinal tract is accelerated by 8-10 hours, while the digestibility of plant fibers decreases sharply the function of the salivary glands and the participation of enzymes in the digestion of carbohydrates; The use of Ca is reduced by 8.2%, P - by 11.1%; Fe - by 6.3-15.3%; Cu - by 9.5-13.4%.

Feedback from leading companies

We use a dry feeding system for all ages. This is due to the fact that the average air temperature in our region from April to October is kept at a level of +40-45 ° С. Therefore, in terms of hygiene, maintaining the quality of feed and improving the livestock, we are best suited for dry feeding. We use a grain group of our own growing (wheat, corn, barley) and buy protein-vitamin supplements from leading companies for the production of feeds.

Lymar Vasily Alexandrovich,

Chief Technologist of LLC "Agroprime Holding"

In our farm for sows and piglets we use dry food, and for pigs on fattening - liquid. Why such a division? For sows, the strategy of feeding with dry fodders was chosen because they are very sensitive to the acid balance of the feed, and in the dry food these parameters can be controlled and adjusted much more easily than in the liquid one.

Kebal Yaroslav Vladimirovich,

First Deputy Director of LLC "Galychina-Zahid", Lviv region

Frunze Ltd. has been engaged in pig breeding for a long time, and I have been working in the farm for 16 years already. In the Soviet era, when liquid feeding was used everywhere - they cooked porridge, soared - I, like a veterinarian in my specialty, had seen enough of the animal health problems that arose due to the souring of feed. The need for treatment entailed significant economic losses.Now we use mostly dry type of feeding - only at the final stage, on fattening, dry food is watered with soy milk. Such a system has been practiced for five years, since then it has acquired a "soybean cow". The effect is remarkable: the pigs lick the feeders to a shine, in addition, in this way we managed to solve the "eternal" problem with a lack of protein in the feed.

Onoshenko Sergey Panteleevich,

Director of Frunze LLC, Kirovograd region

Among the unique advantages of kashitseobraznyh fodder, firstly, the fact that they are much better digested pigs on the growth and meet the physiological characteristics of this age. Secondly, a significant advantage of the mousse feeding system is the fully computerized management of all processes, which allows the automatic addition or removal of various supplements, prescribe vitamins in addition, or, if necessary, introduce vetopreparations.In addition, compared to dry feeding, the re-use of feed is minimized. Piglets, like small children: when playing, they scatter dry food from feeders. When porridge feed feeding is limited: electronic sensors fix the level of feed in the troughs and give out a predetermined portion only when this is necessary.

Pavlenko Igor Petrovich,

Head of FH "Bastion", Khmelnytsky region

conclusions

Thus, it is the combined type of pig feeding, combining both dry feed mixes and liquid feeds which is the most promising in modern conditions. Their rational combination, taking into account the genetic, physiological characteristics of animals, technological characteristics of production will allow, along with high productivity, to obtain biologically high-grade products of high quality.

For the first time the article was published in the journal "Korm-Info" Corporation "Eurofeed modern animal nutrition"

Based on:husbandry.com.ua, pigua.info